Product Description

Customer High Precision Manufacturer Steel /Pinion/Straight/Helical Spur

Planetary/Transmission/Starter/ CNC machining/Drive Gear

Our advantage:

*Specialization in CNC formulations of high precision and quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Online orders and production progress monitoring

*Excellent price-quality ratio

*Absolute confidentiality

*Various materials (stainless steel, iron, brass, aluminum, titanium, special steels, industrial plastics)

*Manufacturing of complex components of 1 – 1000mm.

Production machine:

| Specification | Material | Hardness |

| Z13 | Steel | HRC35-40 |

| Z16 | Steel | HRC35-40 |

| Z18 | Steel | HRC35-40 |

| Z20 | Steel | HRC35-40 |

| Z26 | Steel | HRC35-40 |

| Z28 | Steel | HRC35-40 |

| Custom dimensions according to drawings | Steel | HRC35-40 |

Production machine:

Inspection equipment :

Gear tester

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

How do planetary gears handle changes in speed and torque distribution?

Planetary gears are capable of effectively handling changes in speed and torque distribution due to their unique design and configuration. Let’s explore how planetary gears handle these changes:

- Speed Changes:

Planetary gears can handle speed changes by utilizing the different gear ratios they offer. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. When the input speed is applied to the sun gear, it gets transmitted to the planet gears, resulting in a specific output speed. By changing the gear ratio, the output speed can be adjusted accordingly. This ability to vary the gear ratio allows planetary gears to adapt to different speed requirements in mechanical systems.

- Torque Distribution:

Planetary gears excel in distributing torque across multiple gear teeth, ensuring efficient torque transmission and load sharing. The planet gears are meshed with both the sun gear and the ring gear, enabling torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. The load is shared among the planet gears, preventing excessive wear and minimizing the risk of gear failure.

- Torque Amplification:

Planetary gears can also handle torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The arrangement of multiple gear sets in a compact design enables torque amplification, making planetary gears suitable for applications that require high torque output while maintaining a smaller physical size.

- Load Balancing:

Another aspect of torque distribution in planetary gears is load balancing. The planet gears distribute the load across multiple gear teeth, reducing the concentration of forces on individual teeth. This load balancing capability results in improved gear system durability and longevity. It also helps in minimizing vibration, noise, and wear, ensuring smoother and more reliable operation.

- Flexible Configuration:

Planetary gears offer flexibility in their configuration, allowing for the accommodation of changes in speed and torque distribution. The number of planet gears, the size of the gears, and their arrangement can be adjusted to meet specific application requirements. This flexibility enables planetary gears to handle a wide range of speed and torque variations, making them adaptable to different mechanical setups.

In summary, planetary gears handle changes in speed and torque distribution through their ability to adjust gear ratios, distribute torque across multiple gear teeth, amplify torque, balance loads, and accommodate flexible configurations. These characteristics make planetary gears suitable for applications that require precise control over speed and torque, efficient power transmission, and reliable performance.

How do planetary gears handle variations in tooth engagement during operation?

Planetary gears are designed to handle variations in tooth engagement during operation, ensuring smooth and reliable performance. Let’s explore how planetary gears address these variations:

- Tolerance for Misalignment:

Planetary gears are designed with a certain degree of tolerance for misalignment. This means that slight variations in tooth engagement due to manufacturing tolerances, assembly, or operating conditions are accommodated without causing significant impact on the gear system. The gear teeth are carefully designed with appropriate profiles, clearances, and backlash to allow for some degree of misalignment while maintaining proper functioning.

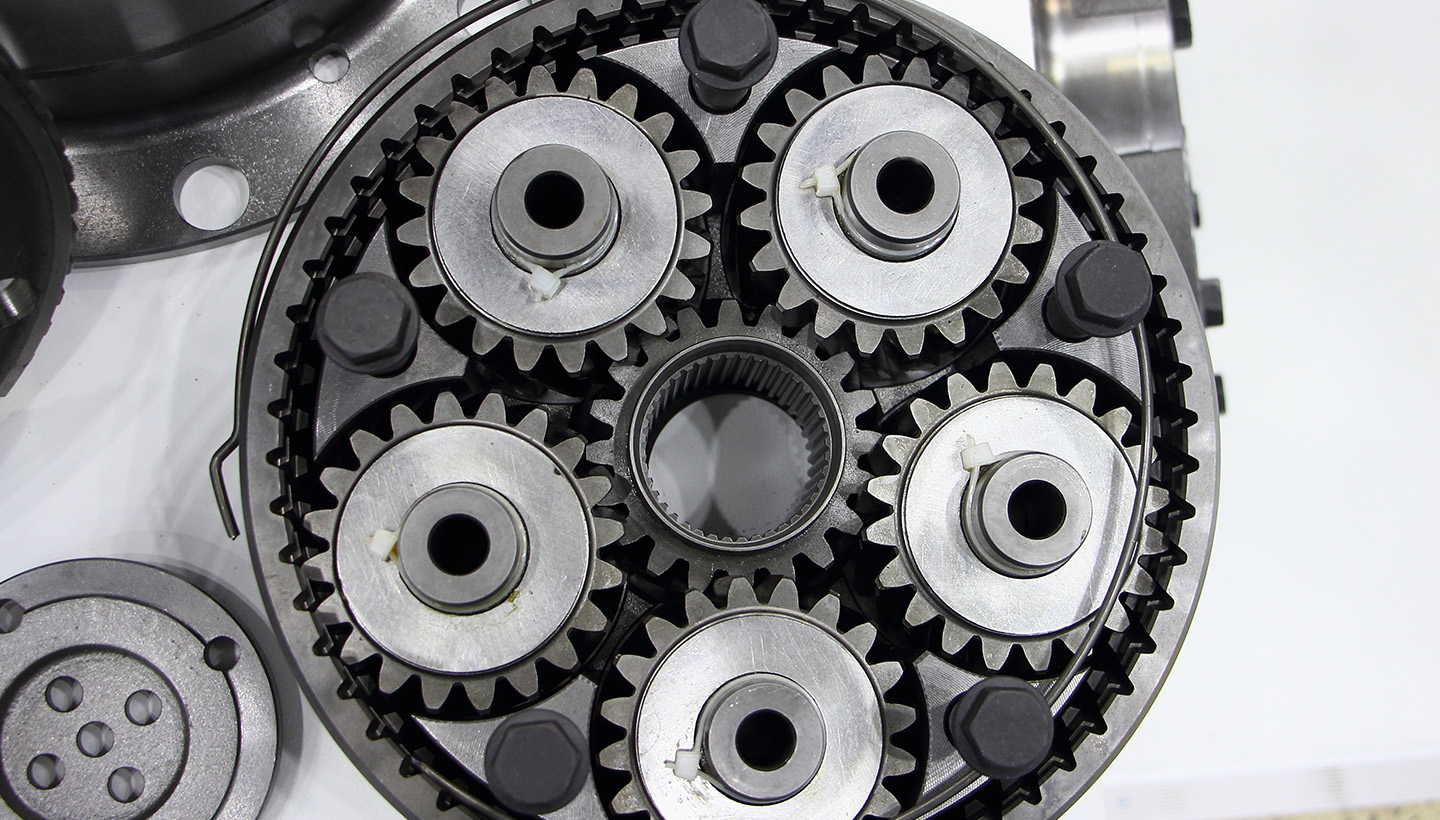

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load across multiple gear teeth. Each planet gear shares the load with the adjacent gears, reducing the stress on individual teeth and promoting even tooth engagement. This load distribution capability helps minimize localized wear, noise, and vibration, resulting in smoother and more efficient operation.

- Flexible Mounting and Support:

Planetary gears are often mounted on flexible support structures, such as bearings or flexible couplings. These components help absorb and compensate for small variations in tooth engagement during operation. The flexible mounting and support systems provide some degree of flexibility and compliance, allowing the gears to self-adjust and maintain proper tooth contact under varying operating conditions.

- Lubrication and Cooling:

Proper lubrication and cooling play a crucial role in handling variations in tooth engagement. Lubricants reduce friction and wear between gear teeth, ensuring smooth operation and minimizing the impact of tooth engagement variations. Additionally, effective cooling mechanisms help dissipate heat generated during operation, preventing excessive temperature rise that could affect the gear meshing performance.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques. This robust construction enhances the gear system’s ability to withstand variations in tooth engagement. By ensuring high-quality gear components, proper heat treatment, and stringent quality control, planetary gears are built to handle the dynamic loads and variations encountered during operation.

In summary, planetary gears handle variations in tooth engagement through their tolerance for misalignment, load distribution among multiple planet gears, flexible mounting and support, effective lubrication and cooling, and robust construction. These design considerations and features enable planetary gears to maintain proper tooth contact, minimize wear and noise, and ensure reliable performance in various applications, including automotive transmissions, industrial machinery, and power transmission systems.

Can you explain the unique design and structure of planetary gears?

Planetary gears possess a unique design and structure that sets them apart from other gear systems. Let’s explore the distinctive features of the design and structure of planetary gears:

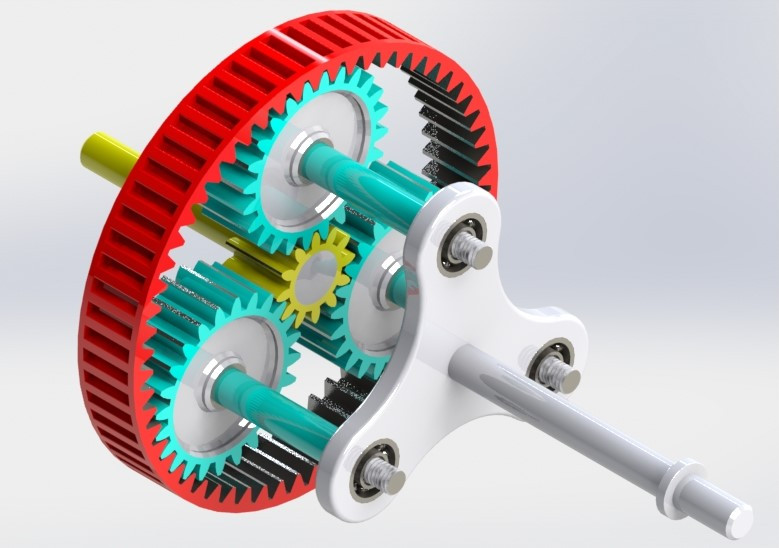

- Components:

A planetary gear system consists of three main components: the sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Internal Gear Meshing:

One of the distinguishing features of planetary gears is their internal gear meshing. Unlike other gear systems where the gears mesh externally, the teeth of the sun gear, planet gears, and ring gear are located on the inside surfaces. This arrangement allows for a compact and space-efficient design.

- Orbiting Motion:

In planetary gears, the planet gears exhibit both rotational and orbital motion. While they rotate on their own axes, they also orbit around the sun gear. This combination of rotational and orbital movement enables the gear system to achieve different gear ratios and torque transmission.

- Central Sun Gear:

The presence of a central sun gear is another characteristic of planetary gears. The sun gear is positioned at the center of the gear arrangement and serves as the primary driver for the overall gear operation. It receives the input power and transmits it to the planet gears.

- Versatile Gear Ratios:

Planetary gears are capable of achieving a wide range of gear ratios. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. By varying the number of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained, providing versatility in speed reduction or amplification.

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load among the gears. This load distribution results in efficient torque transmission and enhanced durability. It also contributes to shock absorption and noise reduction during gear operation.

- Compact Size:

Planetary gears are known for their compact size. The internal gear meshing and the integration of multiple gear sets within a single system contribute to their space-saving design. The compactness of planetary gears is advantageous in applications where size and weight restrictions are critical.

- Wide Range of Applications:

Due to their unique design and structural characteristics, planetary gears find applications in various industries and mechanical systems. They are commonly used in automotive transmissions, robotics, aerospace systems, industrial machinery, and more. The ability to achieve different gear ratios, transmit torque efficiently, and operate in compact spaces makes planetary gears versatile in transmitting power.

In summary, the unique design and structure of planetary gears include components such as the sun gear, planet gears, and ring gear, internal gear meshing, orbiting motion of the planet gears, a central sun gear, versatile gear ratios, load distribution, compact size, and wide-ranging applications. These features contribute to the efficiency, versatility, and space-saving nature of planetary gears, making them suitable for various mechanical systems.

editor by Dream 2024-05-06